Milling PLUS+

In the cold recycling process, the bound and unbound layers of the pavement structure are milled at full depth and recycled by adding new binding agents and additives to produce a stable layer capable of withstanding traffic loads. As a pioneer, WIRTGEN has played a vital role right from the start in promoting this environmentally friendly method.

The economical solution for extensive milling jobs

The W2100 cold milling machine from Wirtgen is a real "workhorse". This extremely powerful machine is at home on large milling sites where high daily production rates are a must. The large milling machine with a standard milling width of 2.20m is used mainly for the removal of complete pavement packages consisting of surface, binder and base course layers in one single pass. The tremendous power of the W2100 is based on tired-and-tested technologies, and the use of state-of-the-art machine components results in exceptionally high productivity maximizing the customer's benefit.

Whether the needs of your project require Full Depth removal or Milling for an overlay, IRONCO’s Cold Planing Division has the right machines for you.

The terms Cold Milling or Grinding are typically used to describe the removal of the upper 1" to 4" of an existing asphalt surface by a Cold Planing machine. This method is used when the underlying surface (subgrade) is structurally sound, allowing for the installation of a new surface and/or wearing courses.

The term Full Removal is typically used when the existing structural section is showing distress, requiring removal and often times a redesigned stronger structural section for complete roadways or parking lots. The Full Removal method can also be used for repairing isolated areas that show distress or section failure. Which is usually coupled with the installation of full depth asphalt.

Not only does the Cold Milling process offer a cost effective method of removal, it has also become an excellent tool in today’s recycling efforts. As precious as our natural resources are, recycling has never been more important! The materials generated by the Cold Milling method are being used both as an alternative in road base materials as well as a substitute for a percentage of the raw materials used in new asphalt concrete products.

Here at Precision Cold Planing we believe that No project is too Big or Small. With our diverse line of Cold Milling equipment and resources, our customers can rest assured we have their project needs covered.

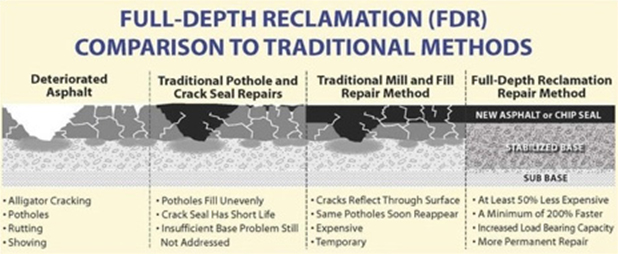

Full Depth Reclamation (FDR)

This process rebuilds worn out asphalt pavements by recycling the existing roadway. The old asphalt and base materials are pulverized, mixed with Portland Cement or Quick Lime and water, and then compacted to produce a strong, durable base for either a new asphalt or concrete surface.

Full-depth reclamation uses the old asphalt and base material for the new road. There's little to no need to haul in aggregate or haul out old material for disposal. Truck traffic is dramatically reduced, and there is little or no waste.

Full-depth reclamation uses the materials from the existing deteriorated asphalt pavement and, with the addition of cement or lime, creates a new stabilized base.

The recycled base will be stronger, more uniform, and more moisture resistant than the original base, resulting in a long, low-maintenance life. And most important, recycling costs are normally at least 25 to 50 percent less than the removal and replacement of the old pavement.

Material Conservation: A Wise Choice

Conserving virgin construction materials through recycling with cement makes smart economic and strategic sense. A century of modern growth and urbanization in North America has depleted once plentiful aggregate supplies. Frequently, aggregates either come from distant quarries at great expense or from local sources offering only marginal quality. Continuing to exhaust these valuable resources to rebuild existing roads only propagates and accelerates the problem. Additionally, if old asphalt and base materials are not recycled, they must be disposed of or stockpiled, increasing transportation costs and utilizing valuable landfill space. In some locales, old asphalt can no longer be landfilled. Environmental laws are becoming stricter, thus adding to the expense of mining new materials and landfilling old.

Conserving virgin construction materials through recycling with cement makes smart economic and strategic sense. A century of modern growth and urbanization in North America has depleted once plentiful aggregate supplies. Frequently, aggregates either come from distant quarries at great expense or from local sources offering only marginal quality. Continuing to exhaust these valuable resources to rebuild existing roads only propagates and accelerates the problem. Additionally, if old asphalt and base materials are not recycled, they must be disposed of or stockpiled, increasing transportation costs and utilizing valuable landfill space. In some locales, old asphalt can no longer be landfilled. Environmental laws are becoming stricter, thus adding to the expense of mining new materials and landfilling old.

Not only is pulverization a key component in the Soil Stabilization process, but it also offers a wider variety of options to today’s construction methods.

As part of the Full-Depth Reclamation process, in-place pulverization is used to create a homogenous mixture of the once existing asphalt structural street section. This not only offers a considerable overall cost savings of approximately 25% to 50%, but a far superior base material product known as PMB (Pulverized Miscellaneous Base). Many agencies, including Caltrans, have recognized it’s benefits and have incorporated it in their specifications as a stand process.

But the use of Pulverization doesn’t stop there. Many contractors use Pulverizers with the application of Soil Amendments. What once was a slow process of turning in soil additives and amendments with motor graders often yielding an uneven mixture has now become a streamlined efficient alternative offering both a true homogenous blend at a fraction of the time... and cost!

So if you find yourself in need of a cost saving base material alternative or soil amendment project, Precision Cold Planing has the equipment and know how to facilitate your projects every need.

We're Always Happy to Help

Get in touch with us today!